Copyright © Huizhou Derun Plastic Technology Co., Ltd. All Rights Reserved. Site Map

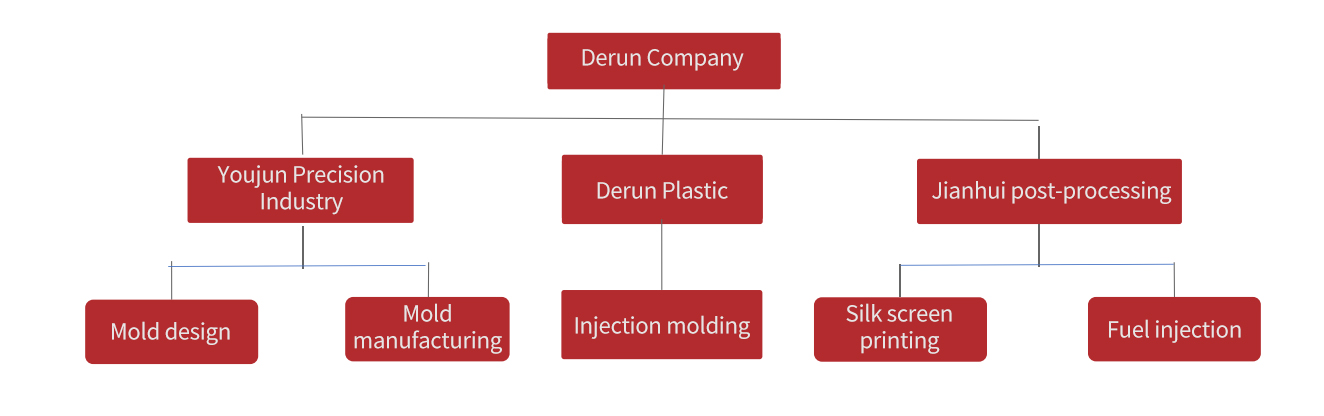

Huizhou Derun Plastic Technology Co., Ltd. is a professional injection molding manufacturer established in June 2020. The company mainly produces plastic products such as injection molded parts, solenoid valves, plastic accessories, injection molds, etc., which are widely used in automobiles, electronics, daily necessities and other fields, and have a good reputation in the market.

Company scale: The company moved to Jiutan Huayang Industrial Park in January 2024. The production workshop is well-organized, the office environment is clean and atmospheric, with a research and development and production team of more than 60 people, 28 60-220T injection molding machines, and complete supporting facilities such as central feeding system, drying machine, manipulator, etc., with an annual supporting output of about 6 million sets.

Company advantages:

1. Advanced technology. The company has experienced technicians and diligent and professional management personnel, famous brand injection molding machines such as Toshiba, Nippon Steel, Nissei, and Donghua, Alfa central feeding system, manipulator and other auxiliary equipment, as well as a full set of high-end testing equipment such as 2.5-dimensional image measuring instrument and microscope, so that customers can rest assured.

2. Quality assurance. The company has successively passed ISO90001 quality system certification, IATF16949 automotive industry quality management system certification, and UL injection molding product certification. Strict quality management and strict production processes ensure customer peace of mind.

3. Customer first. The company always adheres to the concept of customer-oriented, continuously improves and optimizes products and services to satisfy customers and make customers feel comfortable.

4. Exquisite craftsmanship. From product development to mold manufacturing, from injection molding, silk screen printing, spray painting to hot stamping and electroplating, the entire production chain is seamlessly connected, which makes customers worry-free.

5. Favorable price. The company relies on a complete process chain to provide one-stop service, reduce circulation time, compress production cycle, reduce production costs, and high cost performance to make customers feel at ease.

Company History:

Entered Defeng procurement system in October 2020.

Passed IS09001:2015 system certification in September 2021.

Joined Jianhui post-processing project in May 2022.

Entered Guanmiao and Zhongxin procurement systems in July 2022.

Passed IATF16949:2016 system certification in August 2023.

Joined Youjun mold making project in August 2023.